A beautiful example of vernacular Kentish architecture as influenced by the popular Dutch style originating from the 19th Century

Our small works team recently undertook the refurbishment of a Dutch-gabled Victorian gatehouse which is within the curtilage of a large country house near Ashford. The property was in a state of dilapidation that had been expedited from historic condensation and previous poor workmanship.

The main country house and grounds upon which the gatehouse is located within, photo: Kent Guides (c).

The aim of the project was to refurbish the building to a habitable state and to finally sort out the condensation issue once and for all. The process proposed was to use an insulating wood fibre system but to install this via the internal faces of the building rather than the typical external faces method. The internal face of the walls were lined with (the SPAB approved) ‘Warmshell Interior’ system of wood fibre by Lime Green. After fixing, the boards were finished with a lime plaster to suit. ‘Warmshell Interior’ is a practical solution when fitting insulation to the outside of property cannot be achieved. In this case, the building is apart of a country house’s estate and is therefore apart of the listing and also within a conservation area. Due to this status we cannot alter or adapt the outside of the property, it wouldn’t be practical or in keeping with the architectural style of the building – therefore an internal system would have to be employed.

The insulation panels are installed

Both internal and external insulation methods have their challenges, and this was no exception. Inside we had to move all sockets, switches, pipes, radiators, partitions and door frames plus building supports for the new insulation panels, along with all the necessary making good and conservation to the existing structural timbers. It became a large undertaking but the final result was well worth it.

Redec Plasterer Mark gives the walls a final skim of lime plaster

Once all wall fixings and furnishings are moved or temporary disconnected, the Warmshell insulation boards are secured to the internal wall faces. The insulation boards are cut to size and fixed into position (cables for sockets and light switches may need to be extended through the insulation, though this isn’t always necessary). The wall insulation is plastered with lime and then decorated with a suitable breathable paint such as clay based or a limewash. This whole system of insulation uses natural lime plasters, paints and wood fibre boards which allow the walls to breathe – which should overtime cure any condensation issues and work in tandem with the original historic fabric of the house.

Redec Mason Len works to conserve the porch

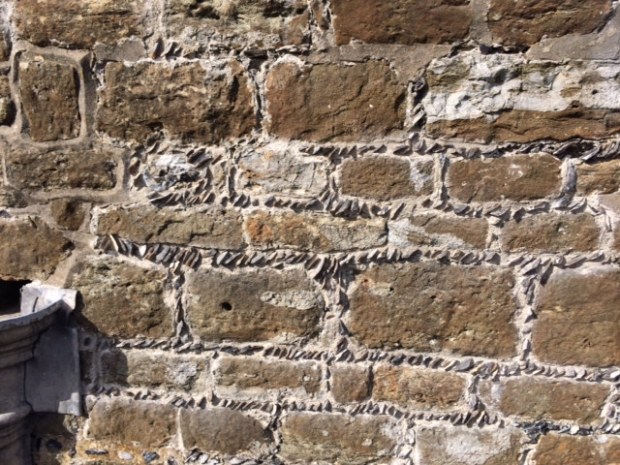

The works also included installation of a new kitchen and bathroom, conservation repairs to windows and structural timbers, lime repointing and brickwork repairs throughout, sheep wool insulation to the loft, a full re-wire, installation of a complete new bay window, roof repairs, glazing replacements, redecoration and renewal of all floor coverings. The works were supervised by Conker Conservation and approved by Ashford Borough Council’s Conservation Officer.

A newly penny-pointed lime mortar wall – can’t see the difference between the new and the old pointing? That’s the Redec quality difference right there!

The finished project