A small section in progress

Our stone masonry section within Redec maybe one of the smallest departments but it is definitely one of the busiest. Running all over the South East of England working on Castles, Stately Homes and Grand Estates, undertaking larger projects such as our recent successful refurbishment to Walmer Castle to small sites where only a small amount of consolidation or repair may be required, they are true #heritageheroes.

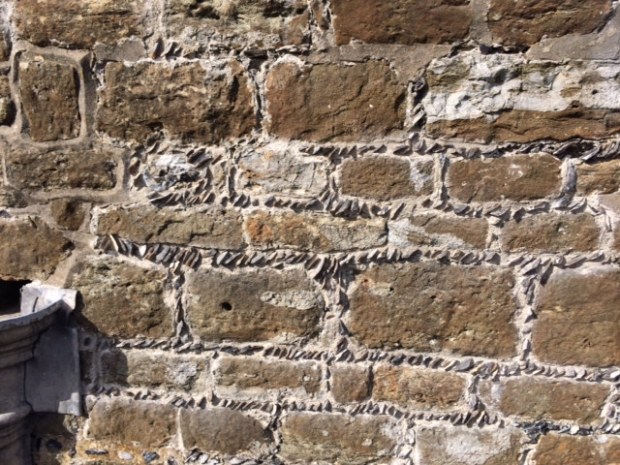

One such project this summer included a huge amount of lime repointing to a galleted rubble-core stone wall. The process of galleting required gallets (or prepared flint flakes) to be placed within the mortar beds to act as spacers/protectors throughout the stonework, they are often dressed into the mortar in decorative patterns with their quality and sizing being very important to the beds they are installed in. It is always important to retain and conserve the original gallets as much as possible, however when further gallets are required the flints must be prepared onsite by means of knapping to match the missing or damaged gallets within the walling that you need to repair.

Before and after to a lintel section

Knapping can be carried out in a variety of methods depending on the purpose of the final flakes. For stone tools and flintlock strikers, chert is worked using a fabricator such as a hammerstone to remove linear flakes from the core of the fint. The process is a little haphazard, so it has to be undertaken over and over to produce enough gallets to undertake the works at hand. Flakes can then be further refined using wood, bone, and slicer tools to perform pressure flaking to create the finer gallets. Once the process is completed (often by the junior member of staff), the gallets are handed to the senior mason who works out a plan based on the quality and sizing to install the best gallets into the prepared walling.

A bucket of gallets, next to a bucket of prepared NH lime mortar

The knapping process can be very painstaking but great attention to detail must be taken to avoid accidents, as such full PPE should always be provided. Selecting an open space, away from human or vehicular traffic is always best and despite being out in the open air, full dust masks should be provided that has been fully face-fitted (which is now a HSE requirement).

Proceeding on this basis will ensure your stone walling is conserved to a high standard.